Bitumen vs Polymer Modified Bitumen: A Comprehensive Guide

Introduction

In the road construction and waterproofing industries, selecting the right binder is critical to ensure durability, performance, and cost-effectiveness. Bitumen and Polymer Modified Bitumen (PMB) are two widely used materials, each offering distinct advantages. This guide provides an in-depth comparison of their properties, manufacturing processes, performance characteristics, and applications to help stakeholders make informed decisions.

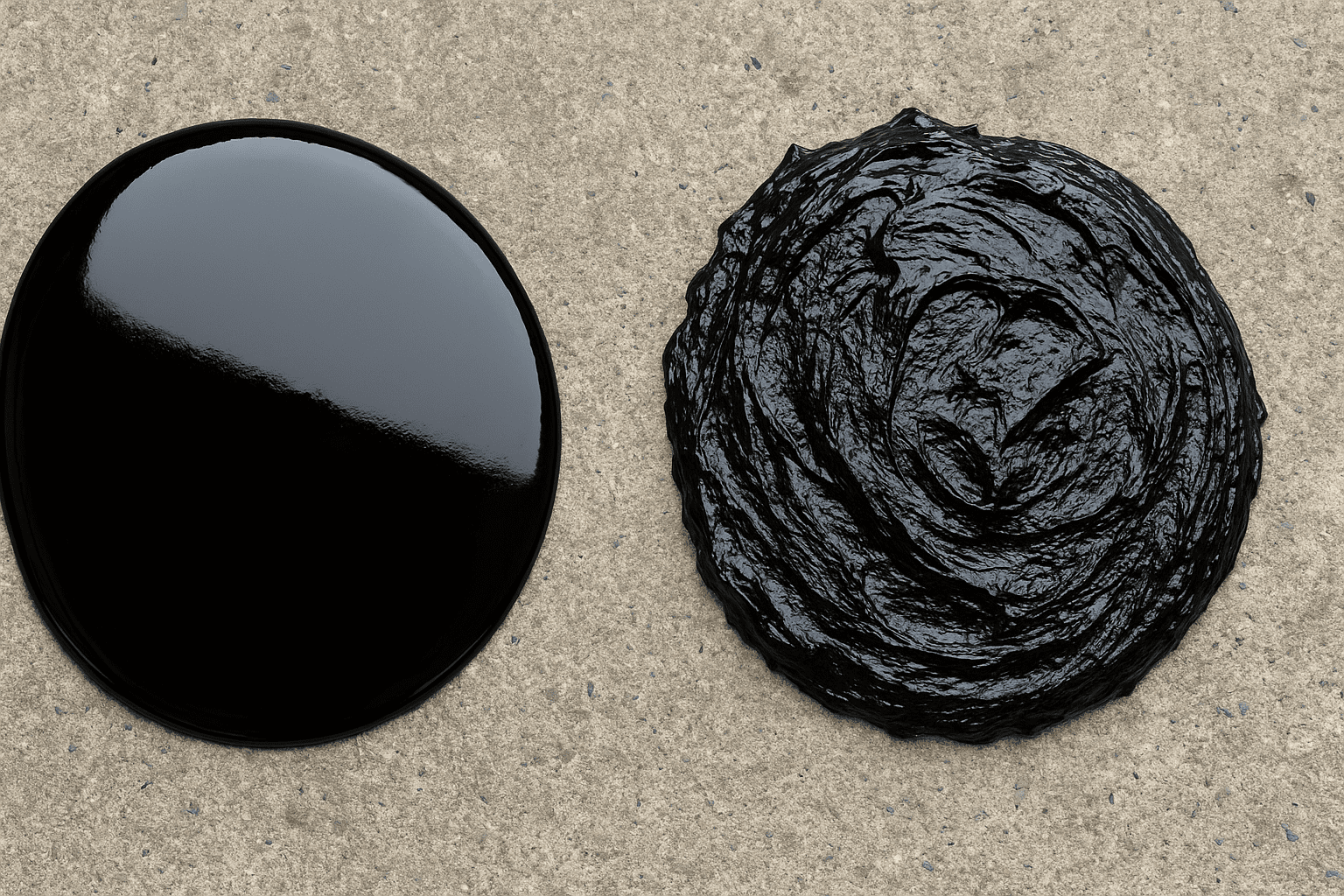

Understanding Bitumen

What is Bitumen?

Bitumen is a viscous, black, semi-solid form of petroleum derived during the refining of crude oil. It serves as a binder in asphalt mixtures and waterproofing products.

Key Properties of Bitumen

- Adhesion: Excellent bonding with aggregates.

- Waterproofing: Impermeable to water penetration.

- Thermoplastic Behavior: Softens upon heating and hardens when cooled.

- Viscosity: Dependent on grade and temperature.

Common Uses

- Road surfacing and paving

- Roofing and waterproofing membranes

- Industrial sealing and insulation

Understanding Polymer Modified Bitumen (PMB)

What is PMB?

Polymer Modified Bitumen is conventional bitumen blended with polymers (e.g., SBS – Styrene Butadiene Styrene, or APP – Atactic Polypropylene) to enhance elasticity, strength, and thermal resistance.

Key Properties of PMB

- Improved Elasticity: Resists deformation under heavy traffic.

- Enhanced Temperature Tolerance: Maintains performance in extreme heat and cold.

- Longer Lifespan: Greater resistance to cracking, rutting, and fatigue.

- Customized Formulation: Tailored properties based on polymer type and dosage.

Common Uses

- High-traffic roadways

- Bridges and airport runways

- Roofing systems requiring high flexibility

- Waterproofing in extreme climates

Manufacturing Process Comparison

| Aspect | Bitumen | Polymer Modified Bitumen |

|---|---|---|

| Source | Crude oil refining residue | Bitumen blended with synthetic polymers |

| Processing | Heating and storage | High-shear mixing and homogenization |

| Cost | Lower | Higher due to polymer addition |

| Customization | Limited | High, based on polymer selection |

Performance Comparison

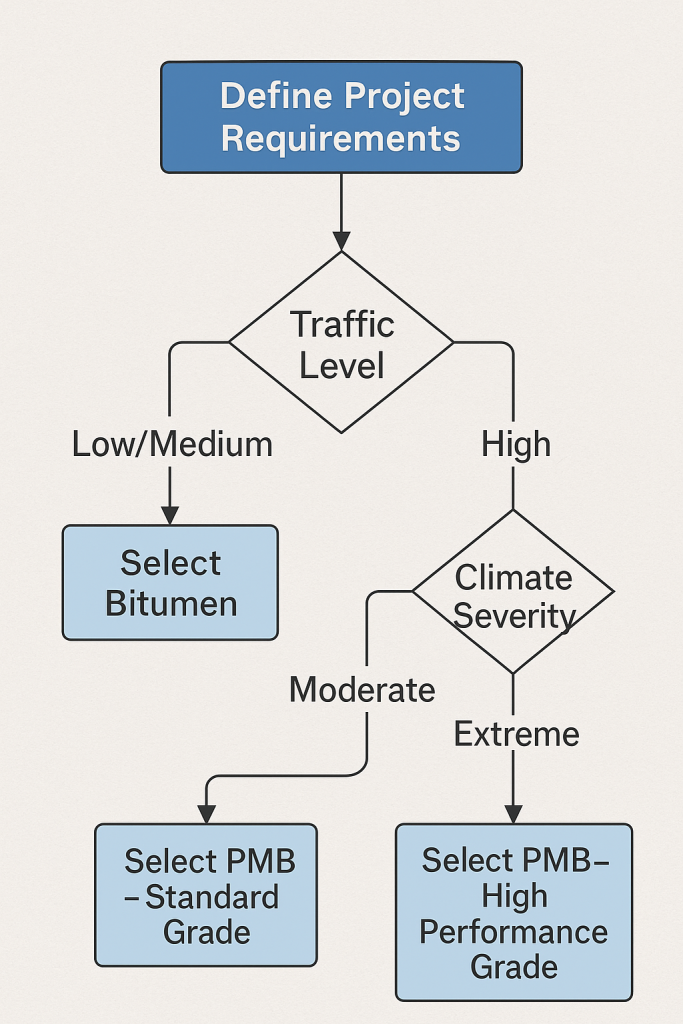

1. Temperature Susceptibility

- Bitumen: Susceptible to softening in high heat and cracking in cold weather.

- PMB: Reduced susceptibility due to enhanced thermal stability.

2. Rutting Resistance

- Bitumen: Adequate for low to medium traffic.

- PMB: Excellent, especially in heavy traffic zones.

3. Fatigue Life

- Bitumen: Moderate resistance to repeated load stress.

- PMB: Superior fatigue resistance, ideal for long-life pavements.

4. Aging and Oxidation

- Bitumen: Oxidizes over time, becoming brittle.

- PMB: Better resistance to oxidation and aging.

Cost-Benefit Analysis

While PMB has a higher initial cost, its longer service life, reduced maintenance needs, and enhanced performance often make it more cost-effective over the pavement lifecycle.

Environmental Considerations

- Bitumen: Recyclable through reclaimed asphalt pavement (RAP).

- PMB: Also recyclable, though polymer separation can be more complex.

- Use of warm-mix technologies can reduce emissions for both types.

Applications at a Glance

| Application | Preferred Binder |

|---|---|

| Rural Roads | Bitumen |

| Urban Highways | PMB |

| Bridges & Runways | PMB |

| Residential Roofing | Bitumen or PMB depending on climate |

| Extreme Weather Zones | PMB |

Decision-Making Flowchart

Conclusion

Bitumen remains a reliable, cost-effective solution for many applications, but when high performance under challenging conditions is required, Polymer Modified Bitumen delivers superior results. By evaluating project-specific factors such as traffic load, climate, and budget, engineers and project managers can choose the most suitable binder to ensure durability, safety, and value.